{{ $t('shop.all.spaetbestellservice.hinweis') }}

Skupina artiklov

Elektronski nadzornik pretoka, PN 100 (will be discontinued)

Application:

The electronic flow monitor monitors liquid media continuously. Its application can be seen wherever flows need to be monitored with minimal pressure loss. The single-piece version of the measuring pin reduces the sensitivity to contamination to a considerable extent. The electronic flow monitor works as per the calorimetric principle. The front face of the sensor is heated up to a few degrees over the temperature of the flow media. When the medium flows, the heat generated in the sensor is dissipated, i.e. the sensor is cooled. The cooling process is a perfect measure of the speed of flow.

The sensor signal is compared with the reference data stored in the micro-controller. Differences between the desired and actual values of the speed of flow trigger off an output signal.

Materials:

measuring element: 1.4301, housing: glass fibre reinforced polyamide

Temperature range:

-20 do +60 °C (medium: -20 do +80 °C)

Media:

Water and aqueous media

Protection class:

IP 65

Electrical connection:

M 16x1.5 cable gland

Advantages compared with mechanical flow monitors:

•optimum temperature compensation,

•intelligent switch property,

•measuring range adaptation, no moving parts,

•simplest installation, commissioning and operation,

•low pressure loss

•intelligent switch property,

•measuring range adaptation, no moving parts,

•simplest installation, commissioning and operation,

•low pressure loss

Optional:

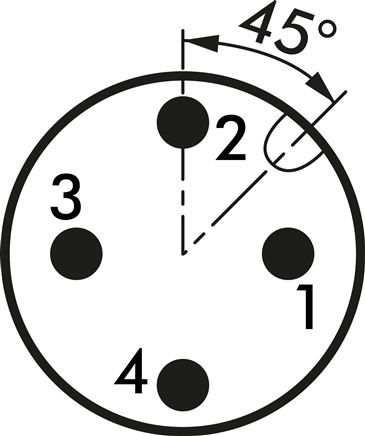

Material of measuring element: 1.4404 -4A, Electrical connection through an M 12 plug (A-coded, 4-pole, 24 V DC) -M12

Switching range depending on the tube diameter (for water):

DN 8: 0,12 - 6,0 l/min, DN 10: 0,19 - 9,4 l/min, DN 15: 0,42 - 21,8 l/min; DN 20: 0,75 - 37,7 l/min, DN 25: 1,18 - 59 l/min, DN 30: 1,7 - 84,8 l/min, DN 40: 3 - 150 l/min, DN 50: 4,7 - 235 l/min, DN 60: 6,8 - 340 l/min, DN 80: 12 - 603 l/min, DN 100: 18,8 - 942 l/min, DN 150: 42,4 - 2120 l/min

{{ $t('shop.all.dokumente') }}:

Catalogue page Atlas 9 (Page 694a_n) atlas9_neutral_seiten/694a_n.pdf

Dokumentacijo dokuneutral/doku_swees_n.pdf

Dokumentacijo dokuneutral/doku_swees_n.pdf

{{ $t('shop.display.artikelgruppe.mehr_informationen') }}

{{ $t('shop.display.artikelgruppe.weniger_informationen') }}

{{ $t('shop.display.artikelgruppe.filtern') }}

Elektronski nadzornik pretoka, PN 100 (will be discontinued):

{{ $t('shop.all.artikelgruppe_n_von_m_artikeln', { anzahlArtikelAngezeigt: anzahlArtikelAngezeigt, anzahlArtikelGesamt: anzahlArtikelGesamt} ) }} {{ $t('shop.all.unverbindliche_richtwerte') }}

{{ $t('shop.all.wochenendversand.hinweis') }}

Pojavila se je napaka!

Pojavila se je napaka, znova naložite stran in poskusite znova.